Refrigeration

We have pioneered the application of the “condensing ejector” principle for refrigeration, air-conditioning and heat pumps. The condensing ejector used as a second step compression in a standard vapor-compression refrigeration cycle improves its efficiency by up to 40%. The technology has been originally developed under US Department of Energy, Invention and Innovation program:

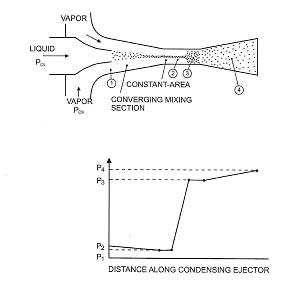

Condensing Ejector is a two-phase jet device in which a sub-cooled liquid refrigerant is mixed with vapor refrigerant producing a liquid stream with a pressure that is higher than the pressure of either of the two inlet streams. The liquid, supplied by a mechanical pump is mixed with a vapor refrigerant of high temperature and velocity supplied by a compressor. The mixing takes place first in a convergent and then in a constant section area of the ejector device. Significant temperature difference and a high relative velocity between both streams results in a high rate of a heat transfer and the momentum transfer. Vapor phase is quickly condensed onto the liquid stream, producing rapid transformation from two-phase into single-phase flow with a resulting rise in pressure, called a “condensation shock”. The theoretical principles and practical experiments are described in the DOE report.

This technology has many applications in fluid transport, refrigeration

and power generation. It may be used to improve the performance of:

1) Industrial and residential chiller/air-conditioning systems,

2) Refrigeration plants and refrigerator appliances,

3) Heat pumps,

4) Gas Liquefaction plants,

5) Cryogenic systems and

6) Automobile A/C.

Condensing Ejector principle and pressure distribution

Condensing Ejector installed on the laboratory stand at Magnetic Development, Inc. |